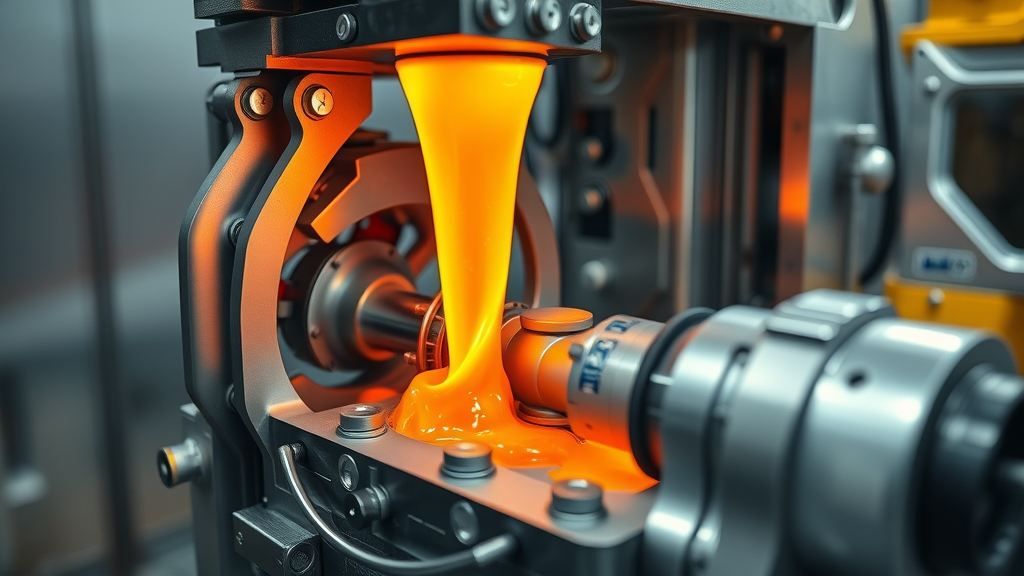

Is Your Production Running at Full Potential? Discover Why Injection Molding Solutions Matter

Manufacturers across every industry face a pressing question in today’s rapidly shifting landscape: how can production lines keep up with rising demand without sacrificing quality or efficiency? The quest for improved output, fewer defects, and minimal waste isn’t just a business aspiration—it’s a necessity for survival. Yet, without up-to-date strategies and technologies, many facilities find themselves bogged down by downtime, excessive scrap, and unpredictable performance. The pathway forward relies on making informed decisions about core manufacturing processes, and at the heart of modern production is the role of innovative injection molding solutions .

Whether you’re producing high-volume commodity parts or intricate components with specialized resins, the consequences of inefficient molding processes are significant. Quality lapses ripple through the supply chain, resulting in missed deadlines and inflated costs. The need to excel at injection molding isn’t reserved for specialists anymore; it has become integral to any operation aiming for durability, precision, and agility. Understanding what injection molding solutions can do for your operation isn’t just about technical know-how—it shapes your ability to remain competitive, agile, and profitable in fast-paced markets.

Understanding Injection Molding Solutions: Elevating Efficiency, Versatility, and Product Quality

At its core, injection molding is the process of shaping polymers into parts of almost any shape or complexity by injecting molten material into a precisely crafted mold. This highly scalable method underpins much of modern manufacturing, but not all injection molding solutions are created equal. Today, manufacturers must navigate choices—such as runnerless systems, advanced nozzle technologies, and manifold configurations—that significantly affect outcomes like production speed, material waste, and finished part quality. Forward-thinking solutions leverage innovations that address common pain points: minimizing resin residence time, enabling rapid color changes, and offering temperature control at individual gates, for example.

The risks of underestimating the importance of advanced molding equipment are tangible. Without robust solutions, even minor inefficiencies—a poorly insulated nozzle, an unbalanced fill, or unreliable valve gate controls—can cascade into chronic waste and unpredictable cycle times. Complexity further increases as businesses grapple with specialty resins, frequent changeovers, and the need to accommodate custom part geometries. Those who overlook the evolution of injection molding technologies risk not only immediate production bottlenecks but systemic setbacks that impair their ability to adapt and grow in a changing marketplace.

How Innovative Injection Molding Solutions Drive Operational Excellence and Results

As an established industry contributor, Osco Inc brings to the table a wealth of expertise driven by decades of developing precision-engineered products. Their approach places high value on balanced fill rates and minimal residence times, ensuring that each molded part lives up to the highest standards of durability and function. Injecting versatility into the process, customizable nozzle systems like their hybrid MGN series handle virtually any resin type and are ideally suited for demanding color changes or clear resin projects, reinforcing operational flexibility.

The practical benefits are clear and immediate. Engineered for minimal waste, Osco’s runnerless systems, valve gates, and manifold technologies cut downtime and material loss drastically, equating to real-world cost savings. For manufacturers, this means higher productive uptime, greater predictability in output, and a marked reduction in scrap. Pinpoint temperature management at each gate provides granular control, essential for tackling applications that rely on consistency and tight tolerances. As operations scale and diversify, these injection molding solutions empower teams to process everything from commodity resins to specialized engineering grades—meeting ever-changing market and customer needs with confidence.

Designing for the Future: Why Versatility and Control Define Modern Molding

The trajectory of injection molding isn’t limited to simply making more parts faster. Instead, it’s shaped by a relentless focus on flexibility and process command. Modern solutions emphasize convertible nozzle systems and individually controlled temperature zones—a response to the reality that product lines must adapt to new materials or customer specs at a moment’s notice. This isn’t a luxury feature; it’s a necessity when brands switch between high-heat engineering resins in the morning and clear, color-sensitive plastics in the afternoon.

The ongoing trend toward customization and small-batch production magnifies the value of precision tools that minimize residence time and streamline color changes. Osco’s diverse tip offerings, wear-resistant gate needles, and adaptable manifold systems are prime examples of how the field is responding to these pressures. Manufacturers able to capitalize on such technologies gain a clear edge—adapting faster, reducing transition times, and maintaining the consistent quality their customers expect.

From Commodity Parts to Engineering Marvels: Addressing Resin Diversity in Molding Solutions

No two manufacturing projects are identical, and resin selection is often the dividing line between success and costly delays. Traditional approaches to injection molding could falter when faced with abrasive, high-performance, or heat-sensitive materials. Advances in gate needle wear-resistance, the ability to maintain meticulously balanced fill rates across multiple gates, and specialized nozzle tips (such as full-body for maximum flow) are now essential features. Osco’s reputation for supporting virtually any resin type—including those that push equipment to its limits—enables precise processing for even the most demanding part geometries.

This breadth not only reduces production downtime due to material incompatibility but also opens doors to innovative industries like medical device manufacturing or automotive engineering. When product integrity is paramount, and cycle times must remain lean, selecting injection molding solutions tailored to resin diversity becomes a strategic decision that echoes throughout the production floor.

Minimizing Downtime and Waste: The Economic Impact of Smarter Mold Technologies

Time is quite literally money in manufacturing, and every minute spent addressing preventable issues—such as suboptimal temperature control or retooling for small part runs—chips away at overall profitability. Injection molding solutions that emphasize easy maintenance, sequential running for valve gating, and customizable manifold systems don’t just enhance technical outcomes; they preserve valuable uptime. Osco’s legacy of designing systems with mold makers and production teams in mind translates into faster setup, lower defect rates, and smoother tool transitions.

The ripple effect of smarter technology reaches the bottom line. Less scrap means lower raw material costs, and reduced interventions mean more time focused on value-adding activities. For competitive operations, these savings fuel reinvestment—allowing for ongoing innovation and expanded market reach—while setting a new standard of reliability on the production floor.

Osco Inc’s Philosophy: Relentless Innovation for Real-World Manufacturing Challenges

Across four decades, Osco Inc has remained steadfast in its mission to deliver creative, effective molding solutions for manufacturers worldwide. Their philosophy is built around anticipating industry needs—engineering products that don’t just meet the status quo but set new benchmarks in precision, control, and operational longevity. This is clearly reflected in their wide-ranging portfolio: from nozzles and valve gates tailored for both single and manifold operations, to temperature and valve gate controllers designed for every level of complexity.

A central pillar in Osco’s approach is design adaptability. Every solution is engineered with both the mold maker and the end-user in mind, blending simplicity with measurable impact. By focusing on elements such as convertibility, wear resistance, and individualized temperature zones, Osco brings real flexibility and cost-efficiency to production scenarios that would otherwise demand constant compromise. Their commitment to innovation is the reason Osco continues to be recognized not just for durable products, but as a reliable industry thought leader intent on advancing molding technology for everyone’s benefit.

This approach—rooted in collaboration, technical rigor, and problem-solving—positions Osco Inc as a voice of authority in the field. Through consistent investment in product engineering and a keen awareness of manufacturers’ evolving challenges, their injection molding solutions shape what is possible for businesses striving for excellence.

Real-World Validation: What Customers Say About their Injection Molding Solutions Experience

In manufacturing, few endorsements carry more weight than the voices of those who put technology to the test on their production lines. When exceptional outcomes align with reliability and service, feedback resonates throughout the wider industry. For businesses exploring new ways to enhance output and efficiency with injection molding solutions, authentic customer experiences can illuminate the real value that cutting-edge technologies deliver.

Great company

—Bernard Murray II

Positive feedback from users serves as a crucial affirmation of the confidence and reliability that solutions like those from Osco Inc can provide. Embracing such proven technology isn’t just about faster parts or reduced waste—it’s a step toward long-term operational stability and industry trust, paving the way for others to experience greater productivity and assurance in their own manufacturing success.

The Role of Advanced Injection Molding Solutions in Tomorrow’s Industrial Success

Forward-thinking injection molding solutions have moved from being industry luxuries to vital components in any modern manufacturing enterprise. The ability to process diverse resins, minimize waste, and guarantee superior part quality all hinge on deploying technologies that prioritize adaptability and precision. With organizations like Osco Inc leading with inventive, well-crafted products, the industry sets a higher bar for what’s possible in uptime, flexibility, and reliability.

As customer needs and production challenges evolve, there’s little doubt that the continued advancement of injection molding solutions will shape the future of efficient, sustainable, and high-quality manufacturing. Those tuned into these innovations are not just prepared for change—they’re positioned to help define it.

Contact the Experts at Osco Inc

If you’d like to learn more about how injection molding solutions could benefit your manufacturing process, contact the team at Osco Inc. 📍 Address: 2955 Waterview Dr, Rochester Hills, MI 48309, USA 📞 Phone: +1 248-852-7310 🌐 Website: http://www.oscosystems.com/

Location and Hours for Osco Inc

Add Row

Add Row  Add

Add

Write A Comment